Spools & Spool Accessories

- Home

- Spools & Spool Accessories

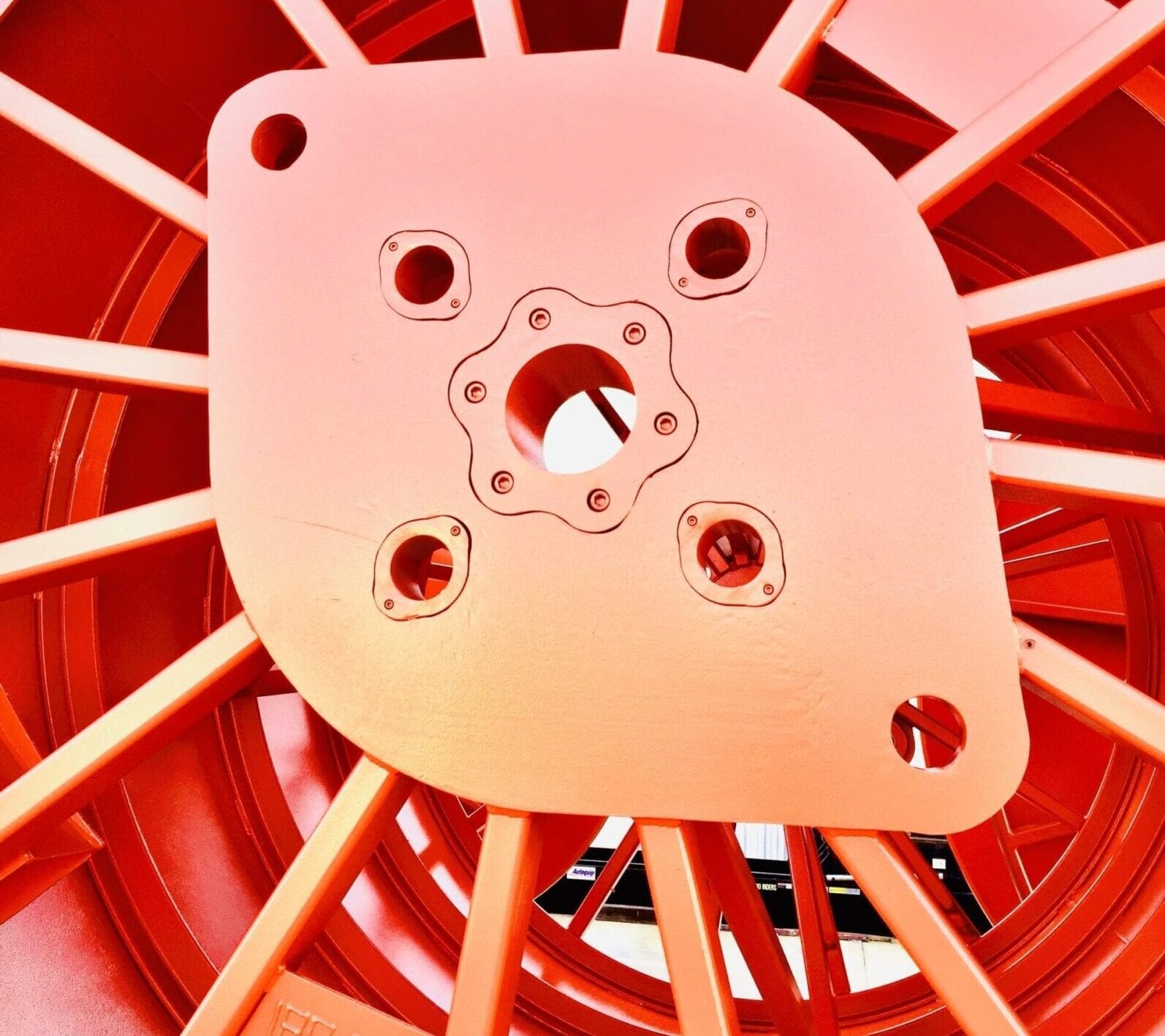

Leading engineer & manufacturer of custom built metal spools, wood spools & spool accessories

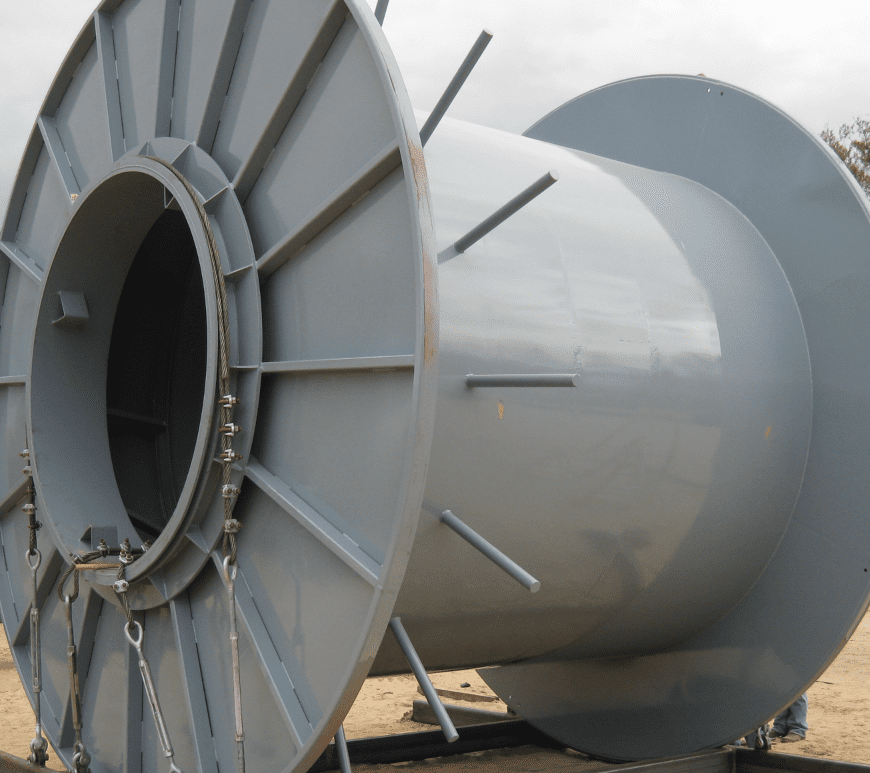

From 2 to 23 ft diameters and rated to as much as 95 metric tons, our designs are backed by more than 30 years of experience and their FEA (Finite Element Analysis) to ensure that customers have a safe and reliable product for years to come. We also offer a wide variety of transport cradles, anti-roll blocks, laydown pallets, hold-down bars, and intricate locking frames that fit into drop-in-drum rigs.

Standard metal spool sizes range from 9 feet to 20 feet and are rated for safe working loads from 20,000 to 200,000 pounds. The in-house capabilities and assembly line process allow for efficient production of multiple steel welded spools simultaneously.

Our shop capacity and capabilities allow us to engineer and manufacture heavy industrial spools used across several industries such as oil & gas.

We also DNV certifications on any size spool for any application. Spooltech currently holds several Design Verification Reviews (DVRs) and Type Approval Certifications (TACs) from Det Norske Veritas (DNV GL). Through quality craftsmanship, our spools can be certified to meet even the most stringent standards and to successfully pass assessments and requirements by independent third parties such as DNV GL. Throughout the manufacturing process of each steel spool, each step is rigorously inspected for quality and accuracy.

Various Engineered & Manufactured Spools

Spooltech Inc. has fabricated both wood and steel spools for more than 25 years. Custom spools can be fabricated in sizes as small as 18 inches in diameter to as large as 23 feet in diameter. Standard spool sizes range from 9 feet to 20 feet and are rated for safe working loads from 20,000 to 200,000 pounds. The in-house capabilities and assembly line process allow for efficient production of multiple steel welded spools simultaneously.

WORKING SPOOLS

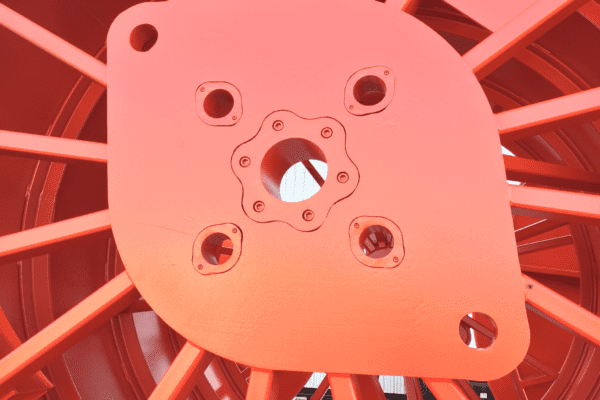

DNV 2.7-3 certifications can be obtained on any size spool for any application. Spooltech currently holds several Design Verification Reviews (DVRs) and Type Approval Certifications (TACs) from Det Norske Veritas (DNV GL). Through quality craftsmanship, our spools can be certified to meet even the most stringent standards and to successfully pass assessments and requirements by independent third parties such as DNV GL. Throughout the manufacturing process of each steel spool, each step is rigorously inspected for quality and accuracy.

DNV CERTIFIED SPOOLS

Custom spools can be fabricated in sizes as small as 18 inches in diameter, and our team of engineers is capable of manufacturing lightweight spools for any number of industrial needs.

LIGHT WEIGHT METAL SPOOLS

Custom spools can be fabricated in sizes as small as 18 inches in diameter, and our team of engineers is capable of manufacturing lightweight spools for any number of industrial needs.

UMBILICAL SPOOLS

Our standard spool sizes range from 9 feet to 20 feet and are rated for safe working loads up to 230,000 pounds with customized designs that can accommodate larger projects. The in-house capabilities and assembly line process allow for efficient production of multiple heavy steel welded spools simultaneously. Our shop capacity and capabilities allow us to engineer and manufacture heavy industrial spools used across several industries such as oil & gas.

HEAVY METAL INDUSTRIAL SPOOLS

Customers in need of coiled tubing shipping spools cradles rely on Spooltech to provide high-quality large fabrication of products across a wide variety of industries including offshore, drilling, commercial, communications and transportation.

SHIPPING SPOOLS

Never get caught down the hole because you have sheared your drive pins from hub wear. The EON Spool eliminates the shearing of drive pins, downtime, loss of productivity, additional spending and needing to replace the drop-in drum from hub wear. Imagine never again replacing a drop-in drum because of hub wear again.

EON SPOOL

Dwellop’s DID in system exceeds other competitors in market in performance, reliability, safety, and capacity. The Drop in Drum system is designed to DNV 2.7.3, drum changes can be performed in less than 30 min, and the compact design allows for easy road passage. From more information on Dwellop spools and other Dwellop products click the link below.

DWELLOP SPOOLS