Cladding

- Home

- Cladding

TRCW, a Division of Spooltech with over 30 Years of Cladding Experience

TRCW, A Division of Spooltech, manufactures, remanufactures and repairs pressure containing and retaining components for Drilling and Production, Surface and Subsurface applications. T

Based out of Houston, Texas, we welcome all projects big or small. Our facility is equipped with all the latest equipment and upgraded welding technology making us a one-stop shop for all your cladding inlay and overlay welding needs.

All cladding projects meet or exceed industry standards.

Clad Welding Processes

- (SMAW) Shielded Metal Arc Welding

- (GMAW) Gas Metal Arc Welding

- (FCAW) Flux Cored Arc Welding

- (SAW) Submerged Arc Welding

- (GTAW-P) Gas Tungsten Arc Welding (Hot wire)

- (GTAW-A) Gas Tungsten Arc Welding (Cold wire)

- (PWHT) Post Weld Heat Treat (In house Stress Relieving on all pipe welds with Heat/Stress treatment units)

Cladding, commonly known as weld inlay and overlay, is the process of depositing a material on the surface of another for enhanced material properties (primarily corrosion resistance). Cladding/Overlay is consists of melting high-performance alloys onto the surface of a base material, typically carbon steel. Adding one or several layers of this alloy to the base material is a cost-effective way of improving material properties, typically corrosion resistance or other mechanical properties.

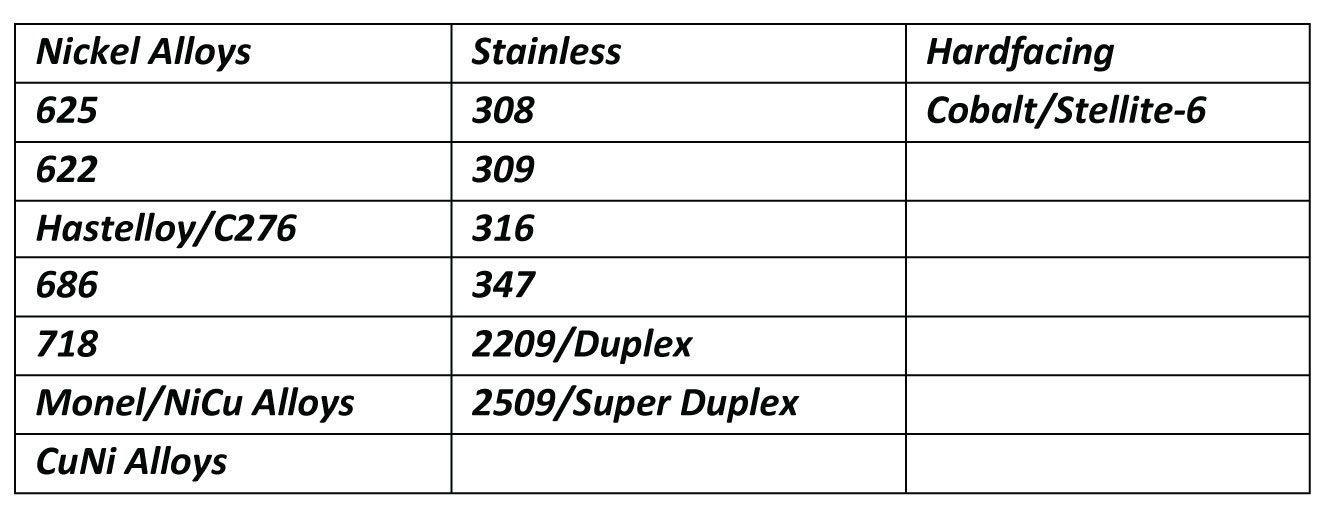

The most prolific alloy used in the Oil & Gas industry is NiCroMo-3 or Inconel 625. We are able to clad a wide variety of corrosion resistant alloys from stainless grades like 316L to combination corrosion/erosion resistant alloys like Cobalt/Stellite-6.

Through our industry leading cladding services we’re able to join dissimilar or malleable metals to a wide variety of materials. Through the use of upgraded cladding processes, we are able to meet all customer needs. We deliver competitive lead times, with both large and small volume capacities as well as prototyping.

Now as a Division of Spooltech, TRCW is able to offer a full array of services allowing us to manage your entire project from concept to delivery.

Cladding Materials

Base Materials: Various Base Materials including 4130, 4140, F22, 8630, etc.

Processes: GTAW-P-HW, GTAW, SMAW, SAW

Numerous Procedures adhering to multiple industry specifications.

Applications in various industries: Valves, valve seat pockets, ring grooves, valve bodies, chokes, marine engine valve stems, pistons, piston crowns, sealing surfaces, pipe, vessels, manifolds, choke and kill boxes, pipe spools, BOP components, frac valves, subsea surfaces, propeller shafts, ball valves, buffer chambers, pipe collars, pipe stems.

Inlay Cladding

Inlay cladding has several advantages over selective plating. The process allows the use of virtually any wrought alloy, ensuring a highly consistent composition, and allowing many alloys to be used which ordinarily could not be plated. Through careful selection of materials, a surface can be attained that is denser, harder and more wear resistant than a plated surface.

Overlay Cladding

Overlay cladding is a process by which dissimilar layers of metals are bonded together into a composite material. This is a metallurgical process which uses no adhesives or filler materials. It is accomplished through the use of extreme pressure and, in some cases, heat. The process can produce what are commonly called single clad (two layers), double clad (three layers), and in some specific instances as many as seven layers. All Clad Metal Specialties overlays are custom made to your exact specifications. Our processes have the capability of bonding such dissimilar metals as nickel to gold, tin to copper, silver to aluminum. The combinations available, limited only by the designer’s imagination, can be manufactured in widths from .100″ to 5″, and thicknesses from .001″ to .125″.

TRCW with Spooltech provides cladding for a variety of use cases for our on-shore, offshore, subsea, chemical, and nuclear customers. While TRCW provides best in class cladding services, alonhside Spooltech and we’re also capable of offering various other welding processes and to multiple industry specifications.

Hit your project times and budgets!

At every stage we supervise your project – from concept to delivery we remain hands on.